INTRODUCTION

Len Brownlie is an aerosports expert with 37 years of experience in the sporting goods industry with expertise in wind tunnel testing, and a client list that has included Nike, the United States Olympic Cycling Team, the Canadian Olympic Committee, the United States and Dutch Speed Skating Teams, and numerous professional athletes, his one goal is to empower athletes to go faster using aerodynamics principles. We had the pleasure to get to know about his projects and how he makes it possible for athletes to gain "free speed".

Livia: What is a Sport Aerodynamicist? Talk me through your career path and how you got into this industry.

Source: Edward Harber

Design Portfolio

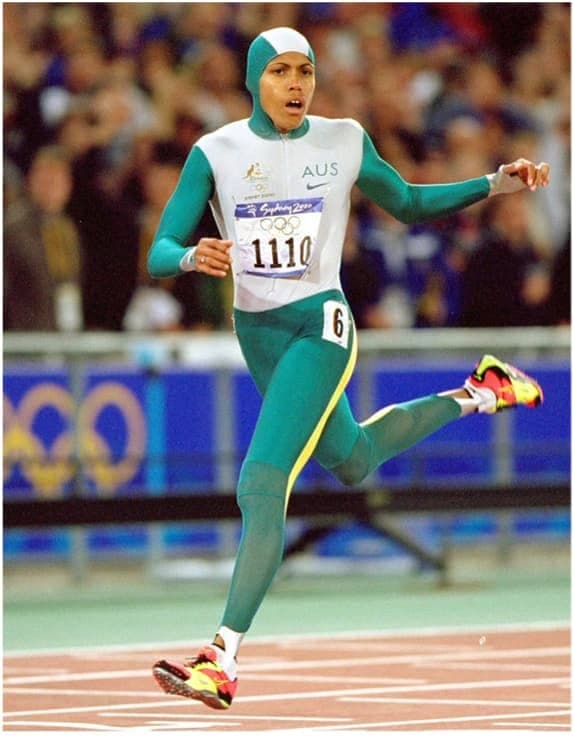

Len Brownlie: Well, this is a very good question. I consider myself a consultant more than an engineer; unlike most engineering, there is a certain amount of art along with the science that is involved in trying to reduce drag. Basically, what a sport aerodynamicist does is to apply some of the principles of fluid dynamics to human motion in order to reduce the retarding force of the air as an athlete passes through it. My own path to this career is a bit convoluted: I was a university track athlete back in the 70s, and given I was not very fast, I was trying to find ways to go faster without resorting to chemical endeavors. And in 1979, an Engineering Professor named Dr. Chester Kyle, who is sort of the godfather of cycling aerodynamics and worked on the US Olympic team 1984 "Funny bikes", published a theoretical paper on how drafting behind another runner would reduce the drag on the following runner, and that inspired me. Ultimately, I ended up doing a PhD in sport sciences and kinesiology, trying to find ways to make aerodynamic apparel for downhill skiers, cyclists and runners. I had some success in that, and Nike had found out about my work. The head of the Sport Research Lab at that time, Dr. Martyn Shorten, was quite intrigued with the concept. He had simultaneously written a theoretical paper on how cleaning up the aerodynamics of tracks spikes could reduce drag on a runner, so they funded my PhD to a limited extent. But by the time I finished it, Nike had moved on to other design concepts for running apparel, you know, neon colors were very hot at that time, and aerodynamic design was not a large component of anything that they were doing. However, in 1998, Nike secured the contract to provide track and field apparel to the Australian and US teams for the 2000 Sydney Olympics, and they brought in a new project manager named Rick McDonald and a new designer named Eddie Harber. Eddie had worked with motorcycle clothing manufacturers, and so he appreciated aerodynamics. The three of us got together and they asked me if I thought aerodynamics could be a factor that would improve the performance of track athletes. I said "absolutely". So over the next two years, we developed what was called the Swift Suit, a tight fitting full body suit with a hood, worn by Cathy Freeman - the torchbearer for Australia who won Australia's only gold medal on the track. It was sort of revolutionary and 20 years later, I got a bunch of phone calls from the Australian Broadcasting Corporation and various Australian newspapers, and they were celebrating the 20th anniversary of her achievement and they wanted to hear more of the back story of how this suit was developed and so forth. So that was the start. Nike was happy with the publicity they got from that project, and they committed to a pretty full technical effort over a number of years to improve the aerodynamics of track apparel, speed skating apparel and cycling apparel as well as swimming suits. And so that launched me on a career with Nike that continued until about 2017. I had also been involved with the Canadian Olympic Association prior to the 2010 Vancouver Winter Olympics and through that association, I was involved in the design of the apparel and a lot of the equipment that was used by Canadian winter sports athletes, and I have continued on with bike manufacturers, bike helmet manufacturers and worked a little bit with the Chinese Olympic Association prior to the 2022 Beijing Olympics as well.

IT IS ALL ABOUT DRAG

Livia: What is the role of aerodynamics in sports? In which sports aerodynamics knowledge can make a great difference in performance?

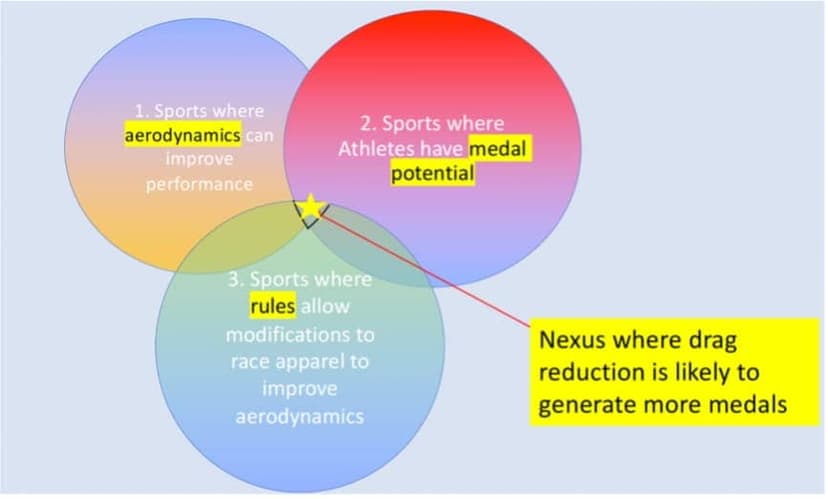

Len Brownlie: After years and years of doing this, I kind of figured out that there are three parameters that need to be met in order to make a measurable impact on the performance of an athlete in a sport, and one of the things is that the sport has to be one in which there is timing involved or there is some aspect which involves aerodynamics. An example of one sport where it doesn't, is curling. There is very little of aerodynamics involved in curling, so there is limited benefit to working on aerodynamics in sports like that. Secondly, if a country is interested in improving the race apparel that their athletes are wearing, they must have athletes who have a reasonable shot at a medal: to move someone from 75th position to 36th position is valuable, but it has no impact on the medal count of the country, so typically it will not be funded, or deemed a priority. Hence, you need to have good quality athletes, you need to have a sport in which you can make an improvement with aerodynamics, and thirdly, you have to have a sport in which the rules are not so restrictive that any benefit you might come up with would be banned; and unfortunately, there are sports that are very rigid in those rules. Ski jumping comes to mind and cycling to some extent as well. In those sports, you have to be careful because there are real constraints on what you can do to improve the aerodynamics of the apparel or of the equipment that the athletes are using.

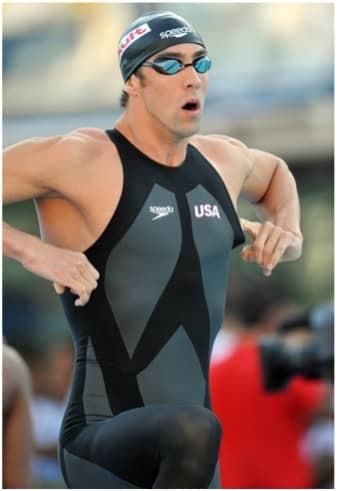

Livia: To what extent are modifications to improve aerodynamics allowed in competitive sports? For example, the Speedo LZR swimsuit was banned as it was adding an advantage to the swimmers wearing them. What was the reason?

swimsuit, the controversial

Speedo LZR Racer. Source:

DPA Picture Alliance Archive

/Alamy Stock Photo

Len Brownlie: The Speedo suit was not that hydrodynamic, but what it utilized was a stretch woven fabric which trapped air when it was on the body. And the rules at that time in swimming were that a suit had to be neutrally buoyant, and the way they tested that was to throw a suit into a swimming pool and see whether it would float or sink. If it floated along underneath the surface, they would give it a pass. The thing about the Speedo suit was that it trapped a lot of air, when the athlete was putting it on. If you go back to some of the videos from races with athletes wearing that suit, you'd notice something: generally, with any swimsuit there would be air coming out of the suit as swimmers dive in and for the first half lap or so; with the Speedo suit, on the other hand, air was coming out of those suits for 10 laps, 12 laps. This made a tremendous difference: air would get trapped between the skin and the suit, so it increased the buoyancy of the athlete. It met the letter of the rules at the time, because the suit itself was not buoyant. It would take 20 to 30 minutes to put a suit on because it was so tight, but in that entire time that the athlete was wiggling into it, they were trapping air in certain areas of the suit and that helped a lot: if you have more buoyancy, you go faster because your legs and torso are higher out of the water. Obviously given the density of water, the more you can get out of the water, the better. And that is essentially what it was doing. It is unfortunate that FINA did not really consider the implications of that, and ultimately other manufacturers started using neoprene, which is obviously porous and holds quite a bit of air as well. So, FINA eventually had to rewrite the whole rule book.

Livia: Is it all about drag reduction or do you also look at lift or any lateral forces?

Len Brownlie: Typically, it is mostly drag that we look at. However, in cycling for example, you can potentially get the "sail effect" with deep rim or disc wheels, where you can harness the side force. The vector resultant of the side force and the drag may create a reduction in the drag on a cyclist. It is sort of similar to what happens with sails on sailboats.

If we are measuring the drag of a cyclist in a wind tunnel, we typically measure not only a full or head on wind with zero yaw angle, but we would go up to 30 degrees of yaw from the head-on wind. A Mechanical Engineering Professor named Dr. Peter Ostafichuk at the University of British Columbia and I adapted a metric from road transport fuel economy research that we call Wind Averaged Drag, which essentially tries to encapsulate the drag you would encounter at various yaw angles in cycling, because when you are going 60 kilometers an hour or less, the side force can have quite an effect on your forward velocity. Cycling helmet manufacturers and bike companies now use it to try and simplify the metrics that are being passed on to the consumer. So instead of saying "well, our bike wheel is the fastest at zero yaw", one can say, "our bike wheel is the fastest at a wind averaged drag over a range of incoming wind directions of up to 30 degrees of yaw at this particular velocity".

As for lift, we do not typically look too much at it. I did a little bit of work with an attempted world record for a model race car. The car had a wing on the back in order to provide downforce, but it provided so much downforce that it created a lot of drag as well, so, there is kind of a tradeoff there, you need traction at high speed, but you also want to reduce the drag to some extent. So that's one application. But typically, we are looking primarily at drag force and just trying to measure and reduce that force.

WIND TUNNEL TESTING: WHERE THE MAGIC HAPPENS

Livia: Let's talk about wind tunnel testing. How do you measure the drag?

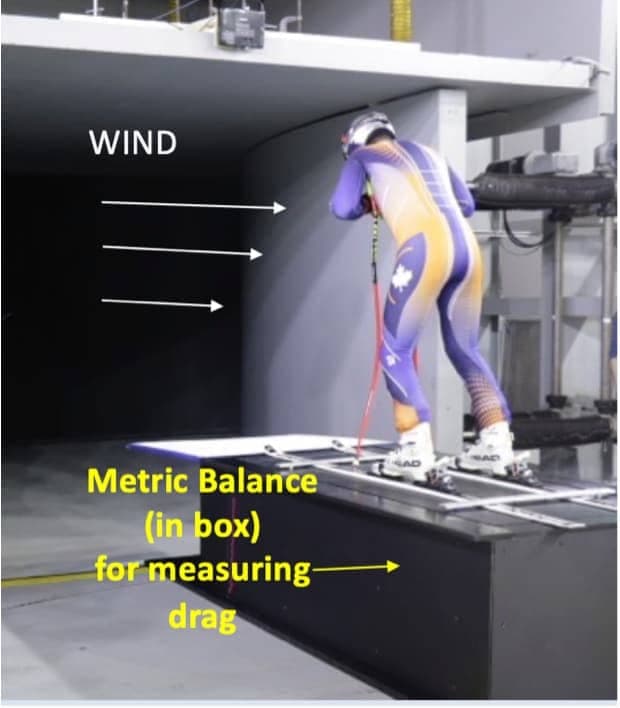

Len Brownlie: Drag is relatively easily measured in a wind tunnel on what is termed a metric balance. Essentially, you can think of a weigh scale that you would stand on in the morning but having three of those at 90-degree angles to one another. So, a typical 6 component balance will provide you with drag if the wind is pushing you backwards. If the wind is lifting you up, that is lift force, and if the wind is coming at you sideways, you are resisting a side force. Associated with those 3 forces are the three moments of roll, pitch, and yaw. I would say that for 80% of the work that I have done, we focus primarily on drag. And most of what we do is comparative, so comparing the drag we see in one configuration versus a modification of that configuration. All your other conditions are made as much the same as possible. The best example in my work is with apparel or clothing, and so very often we would start out with a very regular shape being a vertical cylinder, made of plastic or steel, and not being concerned much with the lift or side force on that cylinder, but rather what is the drag on that cylinder when there is no apparel on it versus when there is a sleeve of a particular textile that is being used.

Livia: What are the measurements that you take in the wind tunnel?

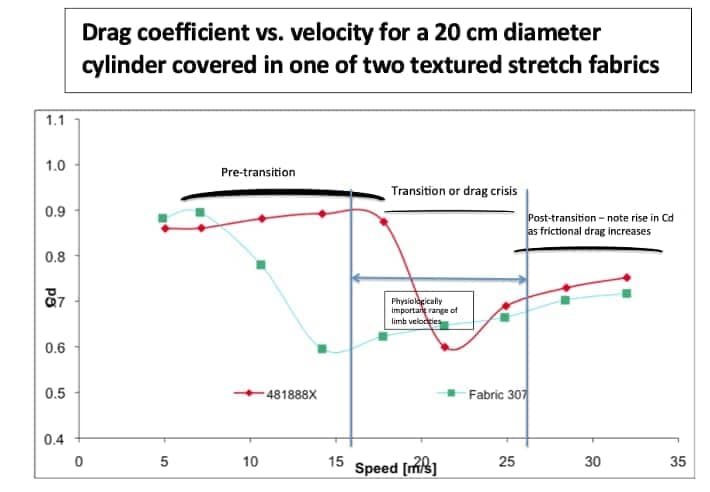

Len Brownlie: What we try to extract from the tunnel is the raw drag numbers averaged through a time window at a particular wind velocity; and what we had found over the years is that air generally follows consistent patterns, but to get rid of some of the random perturbations that occur, it is best to do what is called a q-sweep (q is dynamic pressure, the halved product of density and velocity squared and is less affected by changes in air temperature in the wind tunnel). So, we would typically measure the drag at four or five previously set qs, which correspond to particular velocities. After the q-sweep, we then analyze the data using linear regression as drag is proportional to velocity squared. The idea is to try and get rid of some of the random errors that occur in measurements by using linear regression, and if we get a non-linearity, maybe it is because we have managed to trigger flow transition. Most aerodynamicists would wonder why you would do that, because with an airfoil for example, there is probably not a whole lot of difference that you are going to see at various velocities, but when dealing with the human body and clothing, at the velocities we are operating at for most human movement, you can get some funny things happening, which are hard to predict and hard to measure. Therefore, we have to go through some extreme endeavors to try and hone in on exactly what is happening and differentiate what is real and what is noise, because we are trying to improve the athlete's performance by perhaps 1%; and in order to get that 1% improvement, we are probably looking at a 5 to 10% reduction in drag. And even in a very high- quality wind tunnel, with every factor controlled as best as one can, it is a difficult job to get repeatability of better than 1%, so there is a lot of room there for things to go wrong, as I discovered many times.

Livia: How are the tests carried out? The choice of Fabric textures are very important. Increasing the surface roughness to create a turbulent boundary layer and delay separation can greatly reduce pressure drag and wake size.

Len Brownlie: We are dealing with all types of fabrics and the tunnel becomes even more fundamental in these studies.

I could lay out for you two stretch fabric samples that have a very similar texture and that feel the same. I can show you the samples, you can touch them, you can look at them and they will look identical. You will not be able to determine any difference between them. And yet, when you put them on a cylinder, the aerodynamic behavior of those fabrics will be completely different. This is the kind of scale that we are operating at, where the boundary layer is probably on the order of one to two millimeters. The influence of the fabric can be quite dramatic, even though they look identical. We often use just vertical cylinder tests as a rough screen to reduce the number of potential fabrics for a sport suit.

When we worked with Nike, we came up with over 400 fabrics, and over a period of years, tested all of them and obviously there were some that were similar, but there were some that were incredibly different; and those are the ones that in some cases made-up significant portions of aerodynamic suits.

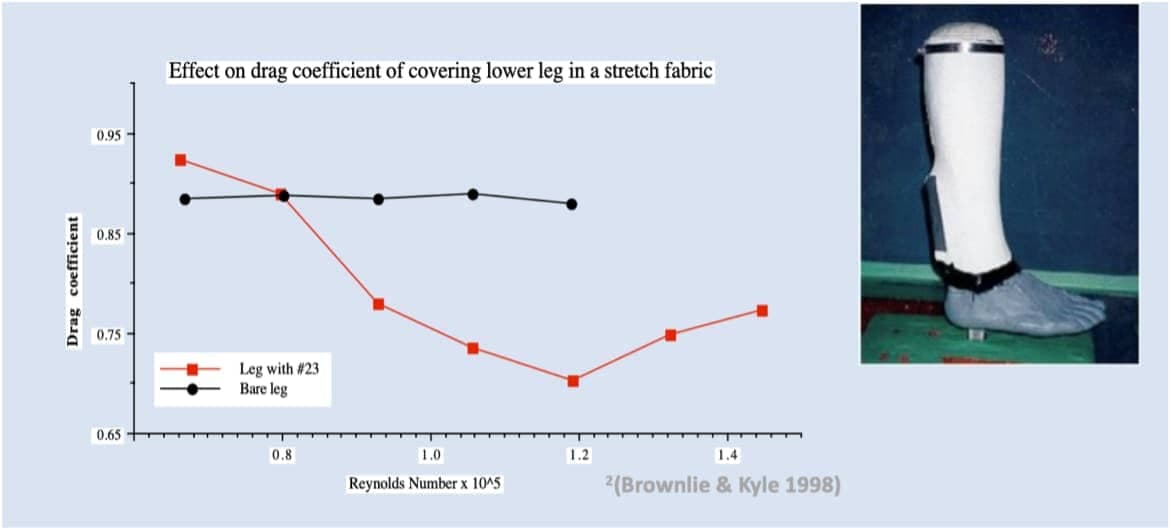

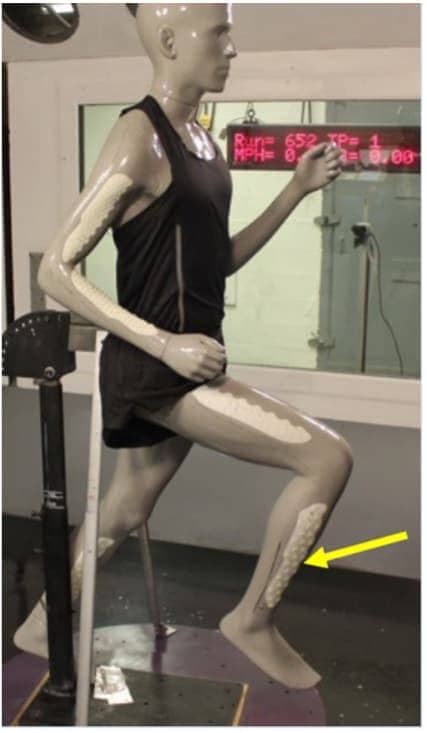

So typically, we start off with studies of fabric-covered cylinders, and I was one of the first researchers to follow this approach with sports fabrics. With a cylinder, you can reduce the drag by up to 50% in our measurements, and given the body is really an assembly of segments of more or less tapered cylinders, my thought, long ago, was that you could probably reduce drag on those segments as well.

Livia: How is flow transition exploited when designing sports apparel?

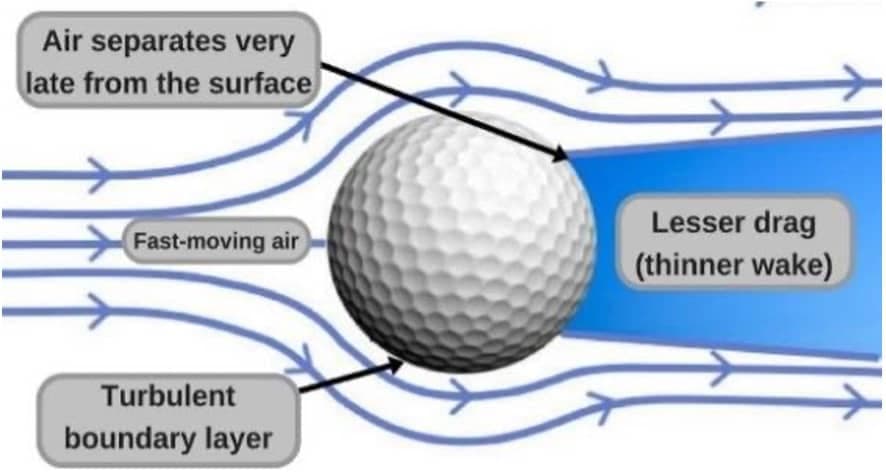

Len Brownlie: Placing a fabric covered mannequin leg into a wind tunnel has turned out to be a very effective way to reduce drag. With appropriately textured fabrics, we roughen the cylinder and see a dramatic reduction in drag: we are getting into the region of "flow transition" and the "drag crisis". When people ask what these terms mean, I tell them it is like putting snow tires on your car: you don't slip as much -- the analogy being that with vertical cylinders in the wind the air will follow the circumference of the cylinder further if the cylinder surface is appropriately roughened. Normally, the flow around the cylinder would break off ahead of the widest part of the cylinder, and by roughening the surface appropriately, you get a turbulent boundary layer at a lower velocity which is characterized by more energy than a laminar one, hence the air will stick on to the surface a little bit further, reducing the low pressure wake area behind the cylinder from perhaps 70 degrees from the front stagnation point to perhaps 110 degrees. By doing that, the pressure difference between the front and back of the cylinder is reduced, and you get less pressure drag. In a nutshell this what we try to accomplish. You will have flow transition at various velocities all the way up the up the leg model which is related to the Reynolds number of that particular part of the leg, based on the diameter and speed of that part of the leg, and in some projects, we were able to reduce the drag on the leg by 20-25% by using several different fabrics to optimally "trip the flow" on each part of the leg. If we could do that on the leg model, we probably could do that on the whole body as well. So that has been the goal of most of the apparel research that we have done.

Livia: When does aerodynamic testing come into play into the design cycle of clothing? Is it developed in parallel with all the other areas of research?

Len Brownlie: I am primarily a wind tunnel guy. And if funds are available, we will use wind tunnel testing throughout the entire design process.

We start off with the cylinders and limb models using small wind tunnels where it is less costly; then we move to full mannequins, which nowadays are 3D body scans of world class athletes, and then ultimately, if possible, we would have the actual athlete come into the tunnel. In this final stage, we would use all kinds of braces and guides to have the athlete fixed in one position and limit movement. It is a complex job to do for sports such as speed skating or skeleton, compared to cycling, where the configuration is more naturally set as the body is already fixed on a bike. And in this final test, what we are really doing is giving the athlete a good amount of confidence: they have the best apparel out there and then all this work and research has been for something, helping them go faster.

COMPUTATIONAL FLUID DYNAMICS, STILL A WAY TO GO

Livia: What about Computational Fluid Dynamics ("CFD")?

Len Brownlie: It CFD is becoming much more prevalent. As you know, computing costs

have come down and the software has become friendlier to use. I would

suggest it has great application for fixed shapes. Before the 2010

Winter Olympics, the Canadian Olympic Association partnered with

Bombardier, who had an aerospace division.

Using CFD, they came up with a better design for the bobsleigh cowling.

Normally, it is very time consuming and expensive to physically build

and wind tunnel test different bobsleigh cowling shapes so being able to

play with different shapes in 3D and simulate the aerodynamic

characteristics of each shape was quite helpful. Unfortunately, the CFD

code used at that time could not effectively model the athletes within

the sleigh, t the code tried to model the top of the helmets, but it

wasn't precise enough and we ultimately resorted to wind tunnel testing

of the athletes in their sleds.

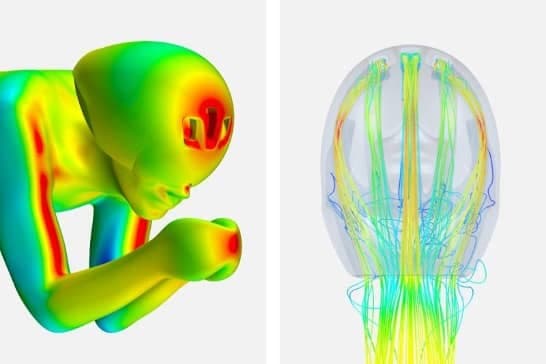

This was a long time ago, now there is a lot of CFD work done on cyclists who are sort of in a fixed shape, but I would suggest CFD still has a way to go in sports aerodynamics in order to effectively model a moving runner, for example, particularly to tease out the difference between running in baggy shorts and a loose top versus one in an aerodynamic suit. My sense is that the mesh size and the number of calculations that are required to establish a valid study when you are talking about a one- or two-millimeter difference in height of an apparel texture, or a vortex generator is pretty tough for CFD to model effectively. In a wind tunnel, I can do 25 to 30 multi-speed tests on cylinders in a day and to make these sorts of iterations using CFD would take far longer and probably be more expensive.

Livia: Do you have experience working with CFD?

Source: Bike World News.

Len Brownlie: In one project that involved the design of time trial cycling helmet, there was some rough CFD done initially to come up with an overall shape and the position of ventilation ducts, and we had about four or five different CFD iterations. With the preliminary data from CFD we tested the physical shapes in the wind tunnel for comparison. However, we found that there was absolutely no correlation between the design and what we were seeing in the wind tunnel. Nonetheless it illustrated to us a feedback loop approach: you design an item with CFD, test it in the wind tunnel, then change the parameters and keep going until you get good correlation between the two. As CFD gets better, it's really important for there to be experimental validation of what is being calculated.

Livia: Are CFD simulations integrated in the design cycle?

Len Brownlie: In the past few years, more companies and researchers are beginning to use CFD as an alternative to wind tunnel testing. With CFD, you get pretty pictures, and people, especially consumers, are fascinated by it. It is an easy way to show you a lot about how the flow goes around an object, doing that in a wind tunnel is very time consuming.

In the wind tunnel we measure drag, but we also either look at doing pressure taps on the model to try and figure out where the flow separation happens and identify zones of high and low pressure; or we do a pressure rake survey behind the model to see if we are making any improvements in the flow around that model. We also use flow visualization techniques such as neutral density helium soap bubbles and smoke trails, to a limited extent, although these methods are not very descriptive. CFD does a much nicer job in illustrating these behaviors if the flow patterns are accurate.

Currently the limit of CFD in sports aerodynamics is that it still does not represent in a precise way a moving object. Up until the last conference that I attended, a few years ago, they could model the aerodynamic effect of different dimples, seam patterns, etcetera on a static soccer ball, but not on a spinning one, so the next step would be to do studies and be able to model a spinning soccer ball to try and see the lift and drag characteristics.

So again, CFD is catching up, but it will take a little while.

Livia: Are CFD and wind tunnel testing also combined with field testing?

Len Brownlie: One aspect that is mostly ignored or forgotten is wind conditions on the field of play. Everything we are doing in a wind tunnel is based on laminar flow. Most CFD calculations are done assuming consistent wind conditions. Whereas when you get to the field of play, and there was some work done by Dr. Annick D'Auteuil at the National Research Council of Canada, where they went out and measured the turbulence levels on an indoor speed skating oval, and noted turbulence levels of up to 2%, which is far higher than what most researchers would have assumed.

This is of critical importance, given that aerodynamic apparel is worn to cause flow transition on some limb segments, but the effect is reduced if the air is already really turbulent. In this case, the wind itself is helping to create turbulence, hence you don't necessarily need additional roughness from textured fabrics, and you might actually create an additional frictional drag if you've got too much roughness on the on the body. It is important to factor that in and most people don't as these studies are difficult to do, there are many scales of turbulence and so forth. It is a complicated problem.

THE POWER OF USING THE RIGHT FABRICS

Livia: Tell me about a project that you have worked on that was most successful in achieving drag reduction.

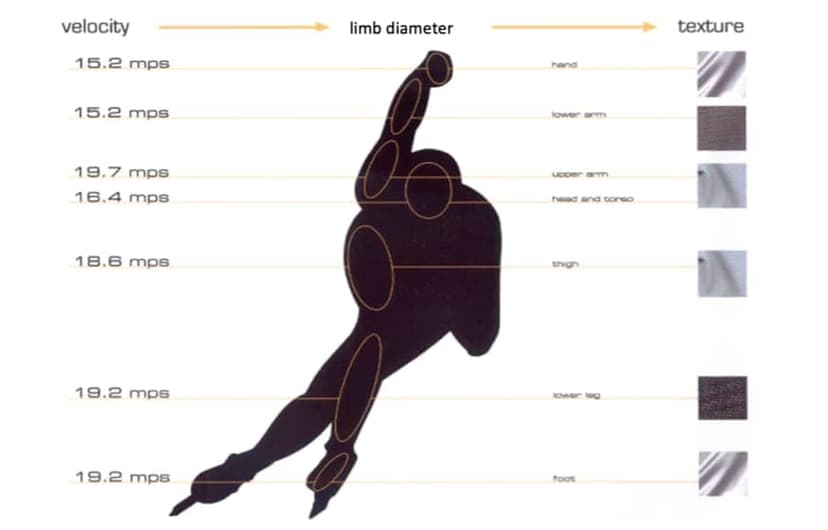

Len Brownlie: The best success we had, hands down, was a long track speed skating

suit, the Nike Swift Skin. Prior to the 2002 Salt Lake City Winter

Olympics, all long track speedskaters were wearing one-piece, tight

fitting, Lycra stretch fabric suits that displayed different graphics

for fashion purposes. Based on the work we had done with the Swift

suit for track and field, we took a full-scale mannequin and applied

different fabric sleeves to different parts of the body. We first did a

lot of cylinder tests, where data was easy to analyze in drag versus

Reynolds number plots. We would look at the Reynolds number at which the

drag was suddenly becoming nonlinear and dropping significantly,

indicating that the fabric covering the cylinder had triggered a drag

crisis. This confirmed that a specific fabric would work well to reduce

the drag of a limb segment at a particular Reynolds number.

You can end up doing three or four fabrics per limb segment. The process is repeated for most parts of the human body, because each limb goes to a different maximum velocity and has a different diameter. With the speed skating suit, we used seven different fabrics for the whole-body suit. There had been a lot of work done on them and the results were initially debated: the Dutch team, when they received their suits, told their newspapers that they didn't appreciate the suits, as they were too tight and uncomfortable. This was because the suits had been developed with an articulated fit that minimized wrinkling when they were in the position of racing. If you stood up, it was very uncomfortable because all the seaming and everything was made so that it would not wrinkle when you were bent over and in an aerodynamic tuck. It wasn't comfortable, but they tried them on, got on the track, and they started setting world records in training. So, despite initial misgivings, they never took them off because they were so much faster. When they got to Salt Lake, the Dutch, and US teams, who were the only teams that had these suits, won every Men's gold medal, and there were also several world records set in those suits. The performances were phenomenal and there was what I would term as a "stopwatch measurable improvement in performance" by skaters wearing the Nike Swift Skin, which is very rare to see in sports. So, the project was very successful, and it actually changed the race apparel that is used in that sport today; because after 2002, all teams followed the trend of designing the suit in the same way Nike had. After the 2010 Winter Olympics Nike decided to stop sponsoring speed skating, but other manufacturers have picked up the slack, using multi-fabric suits which are designed to reduce pressure drag over the limb segments. Over the torso, where pressure drag is limited, you want a very smooth fabric to reduce the frictional component of drag. If you look at the suits currently used, they all have a polyurethane coated fabric over the torso and then some rougher fabrics over the limbs and probably the roughest textured fabric will be on the shoulder, lower arms and calf or lower leg.

100% of all Men’s speed skating medals were

won in a Nike Swift Skin.

INFLUENCE OF FASHION

Livia: We often see track athletes wearing baggy clothes. Why aren't all track athletes wearing the aerodynamic technology?

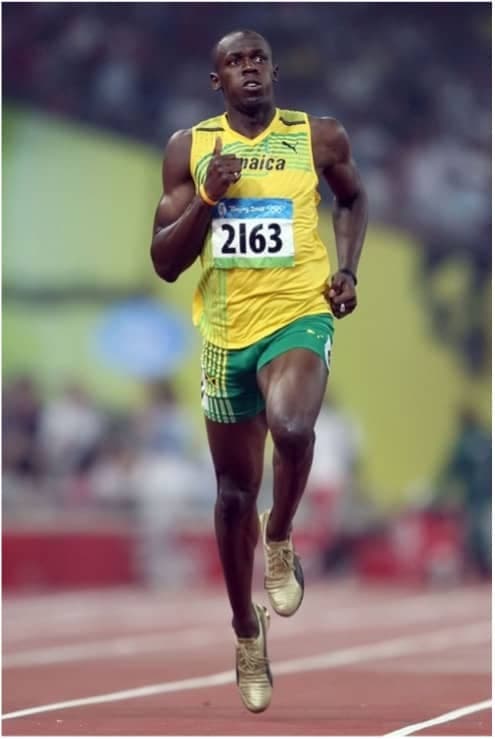

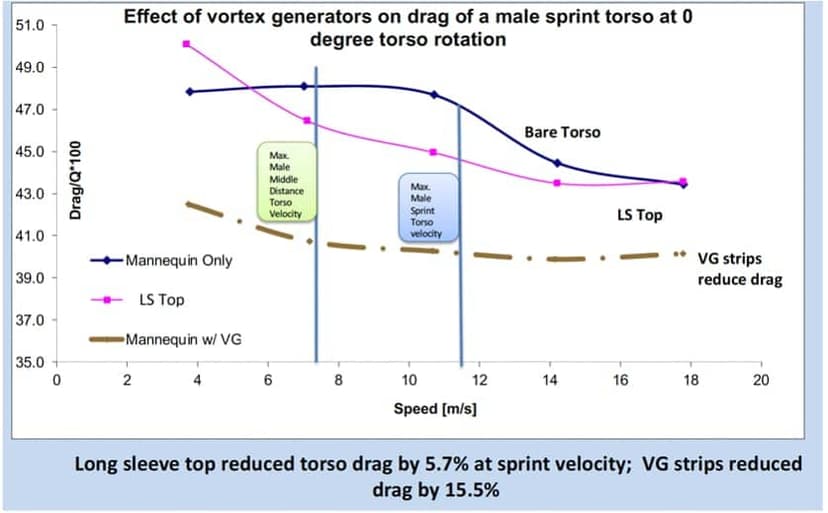

Len Brownlie: It's all about fashion, and the mindset: "I am one of the best of the world, and I prove it without any sort of aerodynamic or technical help". Michael Johnson, who set a 400-meter world record wearing a singlet and half tights, appreciated the suit but didn't see it as really "his thing". This was because he was already on top, and you don't want to demonstrate any weakness to your rivals. Unfortunately, this mindset is also associated with the desire to always, particularly in apparel, have something new and something trendy, not necessarily aerodynamic. In Rio, we had probably the best aerodynamics ever in track, utilizing vortex generators embossed on tape patches and fabric sleeves, whereas in the 2020 (2021) Tokyo Olympics, track apparel designers chose to use a corduroy, pleated fabric that was totally un-aerodynamic, but looked cool. And so, it is fashion sometimes that determines what athletes wear. Form and fashion often work together very well, but not always so.

It is also important to consider the other parameters affecting overall athlete performance in track and field, and one of them is body temperature. For a sprint run, the athletes prefer to be running at 30 to 35 degrees, for example. At higher temperatures, air molecules are more separated depending on the barometric pressure thereby reducing drag slightly, and the muscles work better. Sprinters prefer it to be quite warm, and if that is the case, they do not want to be wearing a lot of apparel: a full body suit for a sprinter, in very warm climatic conditions, is just a no go.

The other thing to keep in mind is that these athletes tend to spend a lot of time in the gym, developing a massive musculature. They wanna show that off, and they simply do not want to be wearing a lot of clothing.

Livia: Vortex generators such as AeroBlade technology were getting more popular. Do they really make a big difference?

Len Brownlie: In 2016 for the Rio Olympics, we had actually moved away from textured fabrics because of the thermal situation of having someone wear a full suit for, say, a marathon. Instead, we developed vortex generators, applied to kinesio tape; and that really worked extremely well. It worked at high speeds, it worked at low speeds and Eliud Kipchoge set two marathon world best performances while wearing these Aeroblade vortex generators on his calves!

Livia: And they are allowed in many sports! Why is it not considered "cheating", given something extra is added to the body?

Len Brownlie: Well, I look at it this way: to my view you are not improving the athlete, you are simply allowing the athlete to express their maximum power. I look at any technological advancement of this kind, as a way to allow the individual to reach their athletic potential. I guess the UCI does not agree with me, as they have fairly recently banned vortex generators on time trial suits.

SPORTS AERODYNAMICS: WHAT IS NEXT

Livia: Is sports aerodynamics getting more attention in the later years? What has changed in the last decades in designing sport items for speed?

Len Brownlie: Well, I would say in sports, it comes down to money. There is a lot of money involved. As an example, every suit we came up with for Nike was estimated to have cost somewhere between a million and two million dollars in research and development. Lately I have witnessed a decline in this type of research, Nike has considerably reduced their expenditures on aerodynamic technology. Certainly, for sports like cycling, there continues to be a lot of work being done on improving the aerodynamics of competitive athletes, their bikes and so forth. However, there are other sports where cash is not readily available; and I think most of the winter sports would fall into that category. The athletes are essentially limited to wearing whatever apparel they are given, and the manufacturers are not that motivated to do much research.

Aerodynamic research in sports seems like it has faded right now. If you look at the International Sports Engineering Association meetings that occur every two years, the number of papers that are devoted to sports aerodynamics probably peaked around 2012, and since then the number has declined. Cycling is really the only exception because they spend a lot of time and money on aerodynamics.

Livia: Every athlete is different in terms of body shape, posture, and technique. Do you see business moving towards highly individual customized items for athletes based on their body features?

Len Brownlie: Most of the times, we are doing essentially one prototype, for a single athlete; and that is absolutely critical for the optimum improvement that we are seeking. We work with each individual athlete to customize their apparel or their equipment. However, this makes it a lot more costly, so at the moment it is only done for few high level athletes.

Livia: Currently, we are seeing a decline in aerodynamic research in sports. Do you think we will see a shift towards the reverse direction soon?

Len Brownlie: Everything in sports research is a cycle, and I have probably seen it three or four times in my career: the field moves to something else and then circles back ultimately, and rediscovers aerodynamics again. So, it is a cycle. I am sure we will go around it again.

Livia: What is next in Sports Aerodynamics? What are the currently the areas of focus to further improve sport performance?

Len Brownlie: I have been reviewing a couple of papers for journals looking at measuring drag during dynamic movement in a wind tunnel, not just for cycling but for other sports as well, using an instrumented treadmill. I find it fascinating as you get a more realistic representation of the dynamic drag on an athlete. This is definitely one area that is being explored at the moment, it will be "noisier" data obviously, but if done properly, we could get some very interesting data out of that.

Something else is vortex generators. I believe that, to some extent, they are not used as much as they could be, and I really see them as being a primary driver of improvement in performance.

Finally, another critical area for sports apparel development, perhaps a bit off from just pure fluid dynamics, is thermoregulation, getting better air flow through garments to improve the thermal comfort of athletes. It is an area in which it is very difficult to make progress, but has tremendous potential; and not just for high level athletes, but for anyone who puts on clothing, particularly with climate change and temperatures becoming hotter. Figuring out ways and methods of improving apparel so that it essentially allows more air to flow through is very important.

Livia: What are you working on at the moment?

Len Brownlie: Not too much I can share. I'm looking at some different applications for vortex generators in the marine environment. For testing, the equivalent of wind tunnels is tow tanks and water flumes. They are slower to utilize, and unfortunately, you can only measure drag in one direction in a tow tank. It takes a long time to get things done, but you can get fascinating data from it. It is another area that I am interested in and perhaps a growth area, we shall see.