Introduction 📢

Werner Lodewijckx is CEO of AutoAccess, a company specialized in designing & manufacturing automotive accessories. One of their product lines are hard tops for pickup trucks. With the WLTP (Worldwide Harmonised Light Vehicle Test Procedure) emissions regulations increasing the pressure, aerodynamics have come into play to safeguard the fuel efficiency of the pickup.

A Changing market

Pickups are having a tough time, especially when it comes to their emissions. The basic shape of a pickup truck is not the most rewarding one when it comes to aerodynamics, with a large frontal area, large open wheel spaces, a chopped-off cabin and an open cargo bay. The hard top covers we design & manufacture are there for functional purposes, like creating extra storage space for tools. But when adding a hard top cover to a pickup truck, one also impacts the aerodynamics. An increase in fuel consumption would be quite a negative aspect for both the customer and the regulators. Therefore, we went to work to make sure the latest cover we designed for the Isuzu D-Max wouldn't increase fuel consumption.

Benchmarking

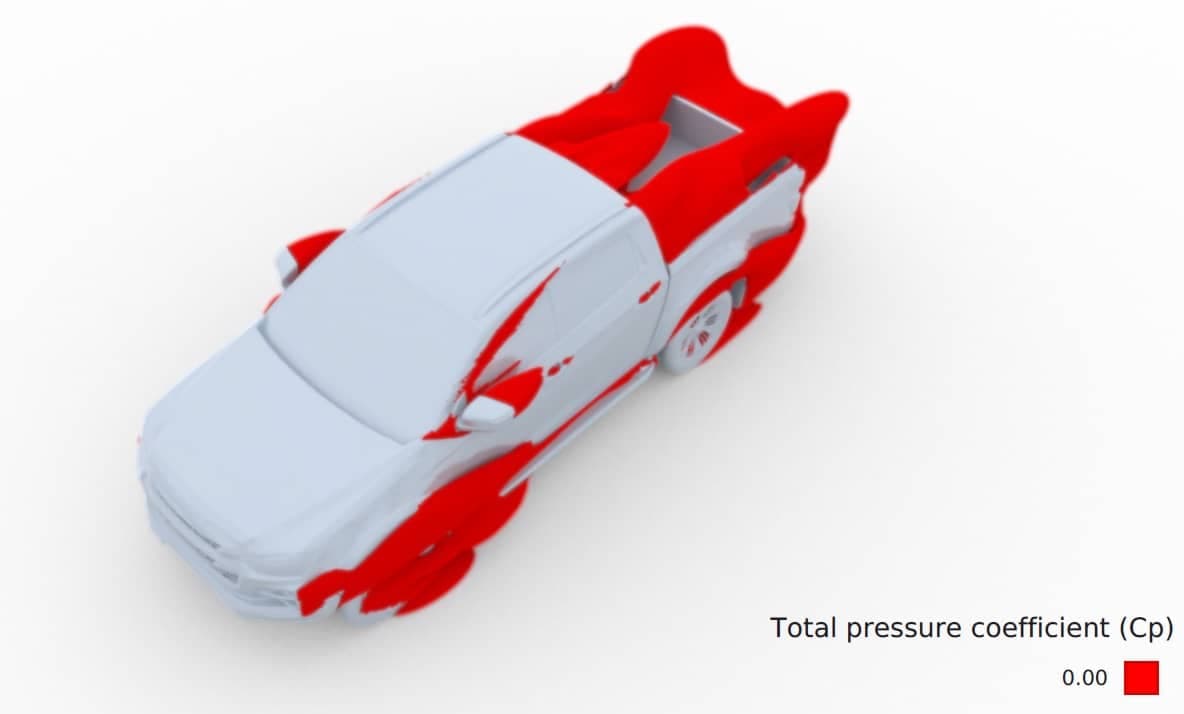

The first thing we wanted to do was to analyze the aerodynamic performance of the pickup truck without hard top cover. This would be our reference for any hard top we would design. As expected, we could see massive flow separation behind the cabin space and then again flow separation at the end of the cargo bay. Our hard tops fit exactly into that space, so we went to work with AirShaper to see how we could minimize the impact on the airflow or even improve it.

Constraints

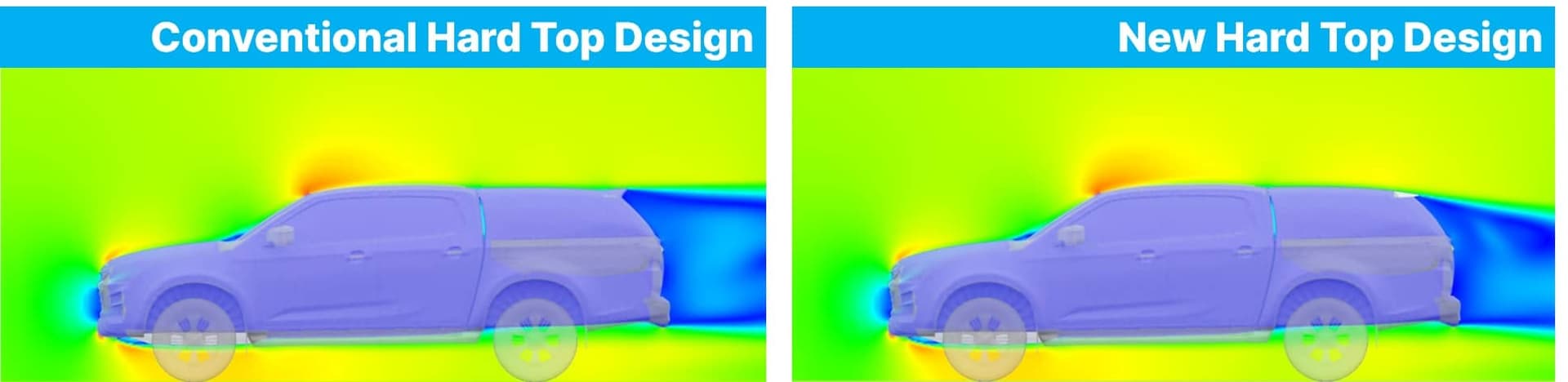

We first analyzed a conventional design, with a visual spoiler at the end of the hard top (to fit the central tail light) and a fairly boxy layout to maximize storage space & accessibility. The first results quickly showed that this kicked up the flow, increasing the size of the wake behind the vehicle and along with it the drag figure. In what followed, we iterated across different designs to balance cargo space, accessibility and a soft downward slope towards the end of the hard top. In a way it makes sense to simply provide the top with a downard curve, to obtain more of a drop shape, but in reality, there is a limit to this: overdo this and you'll see the drag figures go up again (let alone the loss in cargo space). So we kept tweaking it until we had found the optimum.

The results

We ended up with a design that lowered the aerodynamic drag by around 3% compared to a conventional hard top design. And what's even more impressive, it even slightly lowers the drag compared to a pickup truck without a hard top cover. We're quite happy that despite all this we were able to maintain our typical visual style for the hard top.

Interesting links:

AutoAccess