About the Author 📢

Vincent Keromnes works at A2MAC1, a company specialized in benchmarking the performance of cars. Lots of cars. Vincent is in charge of what they call "Dynamic Benchmarking", covering Kinematic & Compliance testing, Energy Management Strategy, Battery Thermal management and so on. With his hands on full 3D models on nearly every major car out there, he couldn't resist tweaking one of those cars on AirShaper to improve the aerodynamics :)

Introduction

The launch of a new generation of the VW Golf is always seen as a major automotive event. A few months ago, we had already ran an AirShaper simulation on the Golf V (one with doors closed and one with Wouter's foot pushing the driver door open 😉) and on the Alltrack version of the Golf VII. So with the arrival of the Golf VIII at A2MAC1, we were curious to see the evolution in aerodynamics over the years. Also, we couldn't stop wondering if there might be ways to further improve fuel consumption with minor tweaks to the car.

From Golf V to Golf VIII

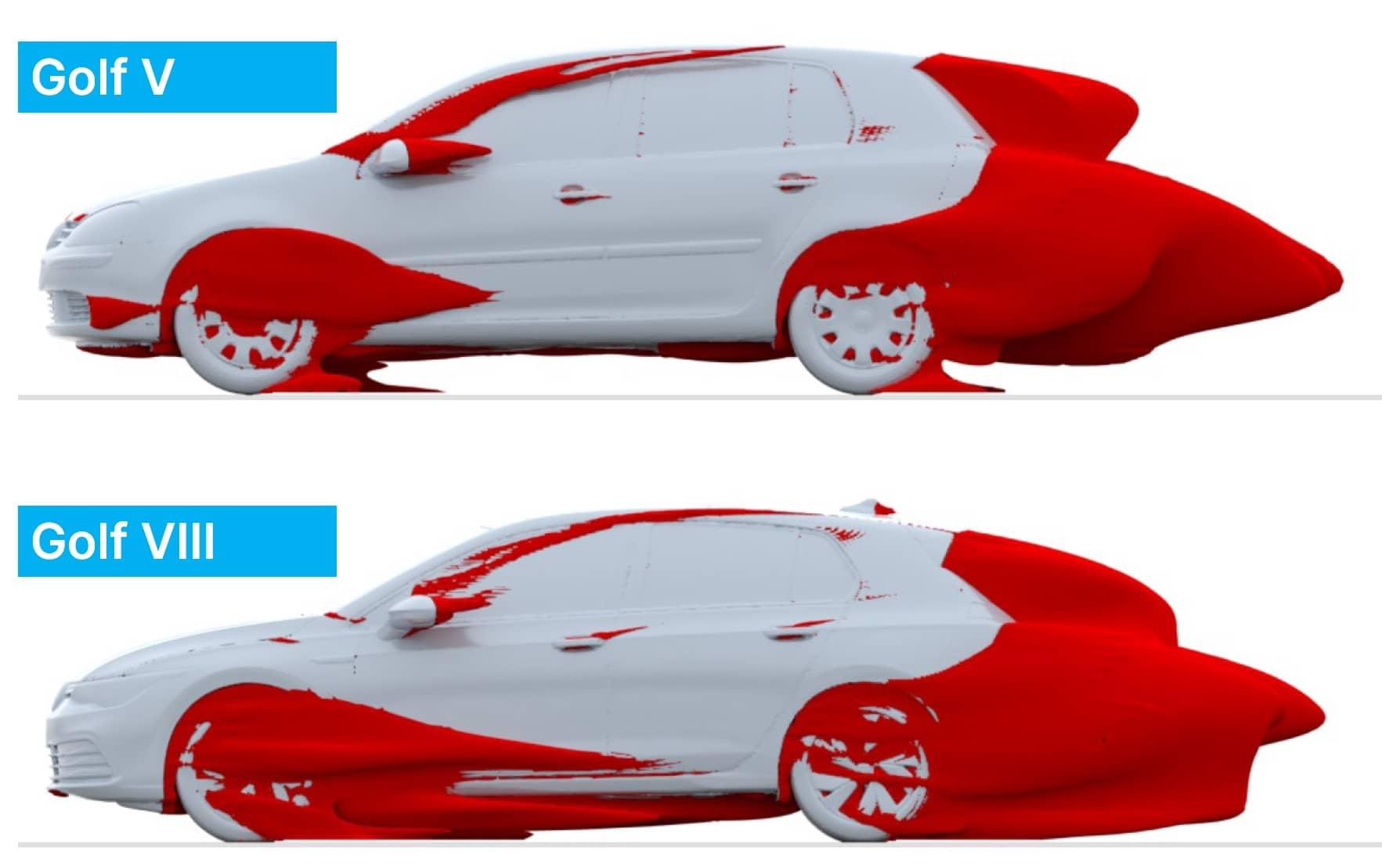

Roofline

As you can see on the profile picture with the "pressure clouds" (isosurface for Cp equal to zero), the aerodynamicists have had lots of influence on the shape of the car, in particular with the end of the roof that is now really going down with a bigger spoiler thus reducing efficiently the height of the wake. You can also notice the A pillar improvement including the side view mirror area.

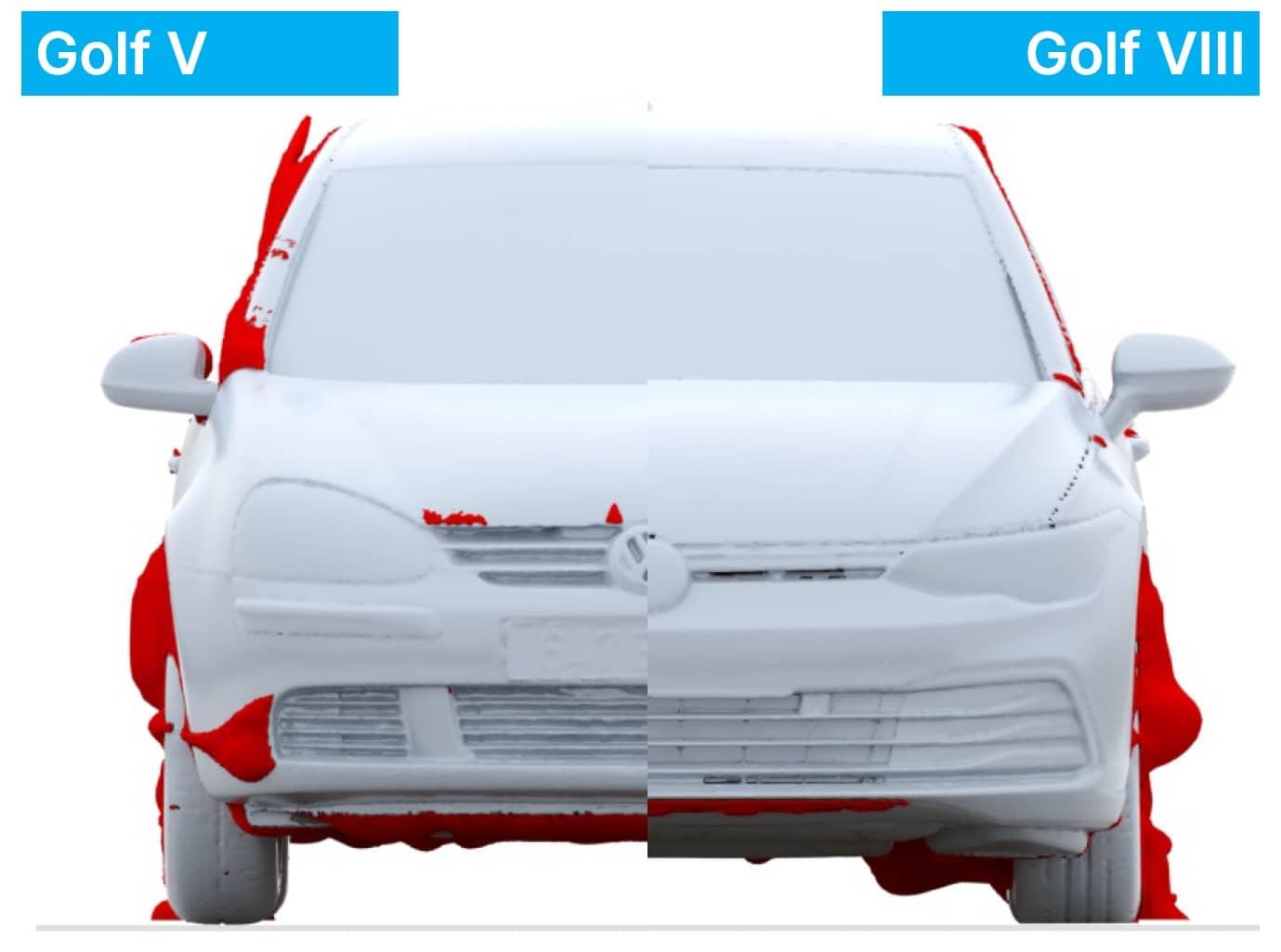

Wheels

The wheels of the VIII are far bigger and larger than on the V. This results in a larger wake close to the ground. But as you can see on the front picture this is balanced by an improved frontal coverage of the tire by the front bumper. As a consequence, the global efficiency of the wheel arch area is improved.

Note: a reader has pointed out that there was no change to the available choice of tyre widths and sizes from Golf 5 to Golf 8

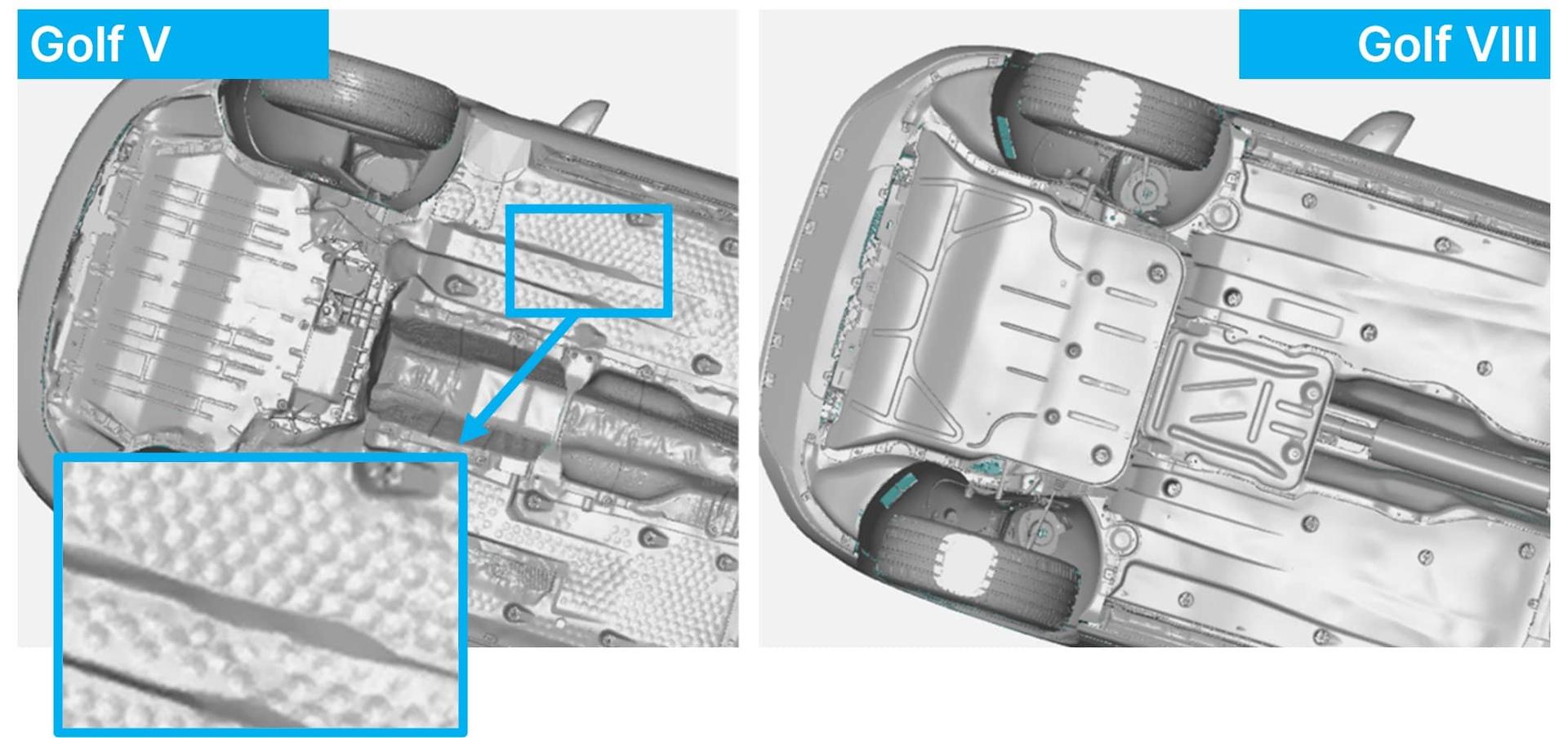

Underbody

It's interesting to see that the famous golf ball structure was applied to the aero shield of the V version but abandoned on the VIII (it was already gone on the VII). At the same time, Audi has been making a lot of marketing around the use of this pattern on the underbody of the etron …

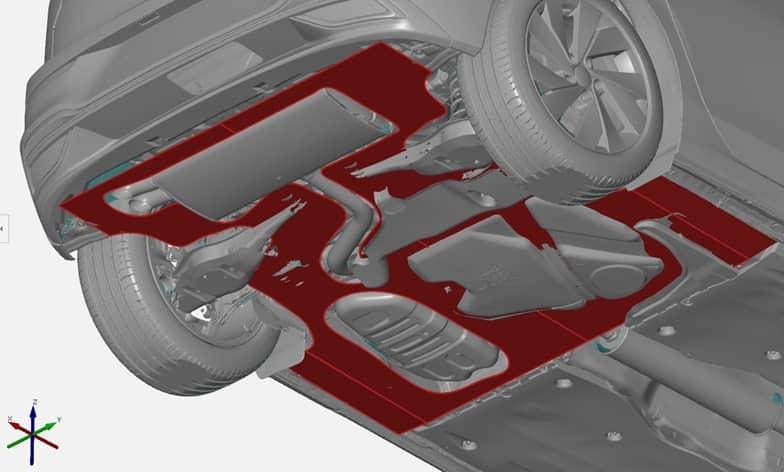

Apart from that side fact, it's quite remarkable that on the Golf VIII, as you can see on the picture, it looks like the underbody coverage extends backward only up until underneath the rear doors.

We could argue that it’s a challenging (and expensive) job to cover the areas with high levels of heat dissipation (exhaust line and associated products) but if we look at the underbody of the eGolfVII we can still see that the underfloor coverage stops before the battery pack.

The numbers

The drag coefficient Cd has been improved by more than 12% from Golf V to Golf VIII. It’s important to notice that at the same time the frontal area has remained the same (about 2.23 sqm). That means that from Golf V to VIII the overall drag has dropped by more than 12%.

Improving the Golf VIII Aerodynamics

Design

Perhaps the underfloor wasn't extended all the way to the back because the gains in efficiency were too small? We kept wondering how much such efficiency gain would be, so we decided to design our very own "aero shield" by applying a few geometry modification. It is nicely cut (well, we did our best :) ) to respect the constraints of the hot parts from the exhaust line. As a consequence, it’s still not perfectly flat but it may be able to contribute to some improvement.

Aerodynamic Simulation

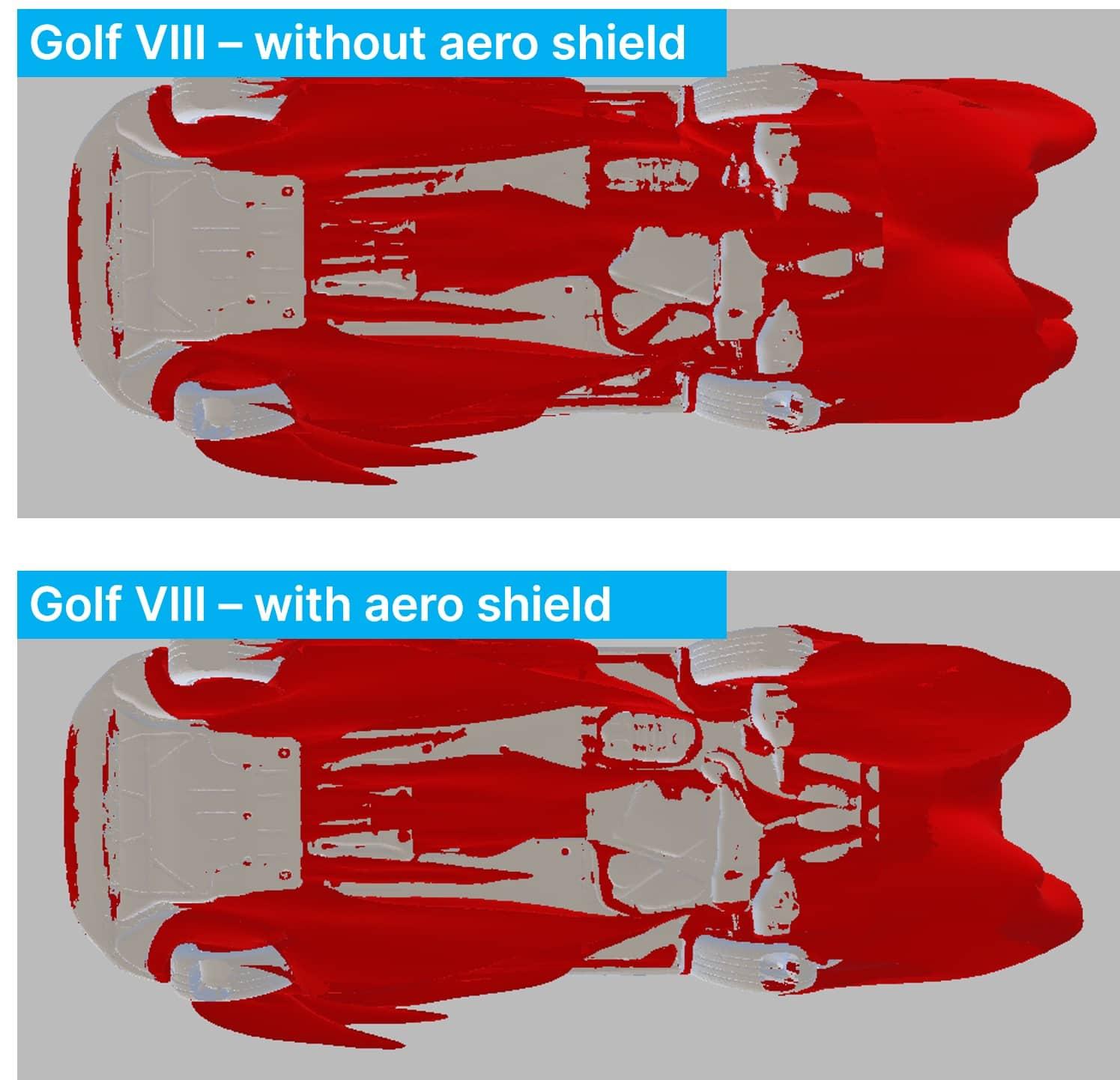

Proud of our design, we then launched simulations of the Golf VIII without and with aero shield to see how it would perform. Below you can see the effect it has on the flow underneath the car. The aero shield helps to maintain a cleaner flow all the way to the back of the car, as evidenced by the reduction in size of these "pressure clouds" (iso-surfaces for a total pressure coefficient equal to zero, in case you're asking :) ).

The numbers

The aerodynamic drag on the car was reduced by around 2% - which is quite significant! This reduction in drag can be extrapolated to around 1g of CO2 savings per 100km. Understandably, car manufacturers constantly need to strike a balance between profitability (the aero shield costs money and hinders maintenance) & emissions (clearly the aero shield helps to reduce emissions) and weight (we're guessing the aero shield would be fairly light). But still, it feels like this would be a fairly "affordable" win in terms of CO2 emissions.

Conclusion

It's been very interesting to see how we can take a 3D scan of an existing vehicle to then modify it to see the effect on aerodynamics. The results suggest that there is definitely still room for improvement in terms of aerodynamic drag & fuel consumption! Sometimes small changes can have a big (positive) effect for the environment :)

Interesting links:

A2MAC1How to Interpret an Aerodynamic Simulation Report

Run Your Own Simulation