Safety is of paramount importance when travelling in the air. This makes certifying an aircraft a long and detailed process. However, over the last few decades, Computational Fluid Dynamics (CFD) has become instrumental in streamlining flight certification. The capabilities of high performance computing along with the flexibility of open source software and improvements in solver accuracy has made the latest CFD codes a viable alternative to expensive wind tunnel testing.

We sat down with David Solar, Head of General Aviation (GA) and Vertical Take-off and Landing (VTOL) Department at EASA to hear his thoughts on the use of CFD in passing aircraft EASA regulations.

What is certification?

Certification is where governing bodies work with manufacturers and operators to ensure that an aircraft and its components are designed, manufactured and modified for safety throughout its life cycle. These governing bodies include the European Union Aviation Safety Agency (EASA), the UK’s Civil Aviation Authority (CAA) and the Federal Aviation Administration (FAA) in the United States. Each authority defines a set of regulations which a new aircraft or operation needs to comply with. So to prove the airworthiness of new developments, manufacturers have to conduct comprehensive testing programmes.

The history of certifying aircraft

Before Computer Aided Design (CAD) and Finite Element Analysis (FEA), flight certification had to rely on many physical flight tests. For example, the certification of the Anglo-French Concorde supersonic transport project in 1960 required six development airframes which flew for 5,127 hours [1]. Although, this project was arguably the most ambitious of it’s time.

Fast forward to 2014 and certification of the Airbus A350 was achieved with five aircraft and only 2,600 hours of flying [2]. Whilst the A350 may not have been the technical leap of Concorde, it arguably exists in a much more stringent regulatory era.

The dangers of test flying

Historically, test pilots have been revered due to the hazardous nature of their work. "Flight tests were only experimental and the risks pilots were taking was a big unknown at the time, which is why their life expectancy was short in some cases," explains Solar.

"Now however, it has evolved significantly. Whilst there is always a risk to the first flight of an aircraft, simulations give us some confidence in how the aircraft will perform aerodynamically as well as it's landing qualities."

The risk of flight tests was demonstrated by the loss of the prototype BAC 1-11 and its seven crew members in 1963. The test was investigating the aircraft’s characteristics during stall and the high angle of attack lead to the wings blocking airflow to the control surfaces on the high tail. This resulted in deep stall, which is a specific risk to this type of aircraft. Sadly, this was not well understood at the time and was unrecoverable.

How are today's aircraft certified?

The EASA type-certification process has four main steps [4]. How a manufacturer goes about completing these steps will vary, but is always after discussion and agreement with EASA.

-

Technical Familiarisation and Certification Basis

-

Establishment of the Certification Programme

-

Compliance Demonstration

-

Technical Closure and Issue of Approval

The first two phases start before there is a completed design or a physical aircraft. CFD is used extensively to optimise the key performance characteristics of an aircraft, according to the specific requirements of the project. Presenting the concept and the CFD results to EASA, the two parties can come to an agreement about the exact nature of the certification process. This will be unique to each aircraft.

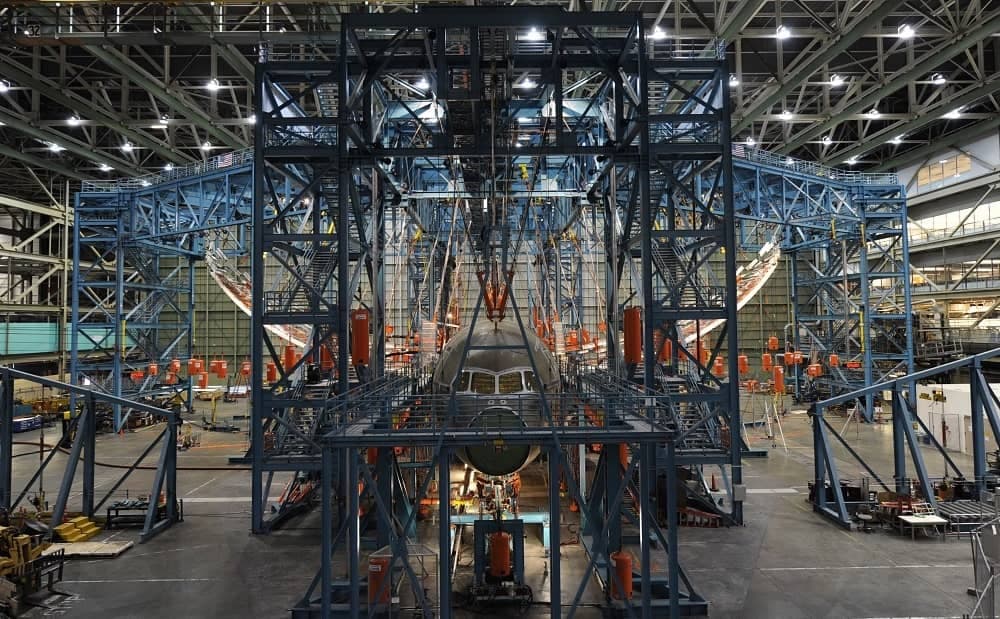

Once the certification programme has been agreed, the next stage is Compliance Demonstration and Technical Closure and Issue of Approval. This is where the manufacturer needs to demonstrate that an aircraft meets the requirements of its type approval. Generally, this comes down to proving its structural integrity and illustrating it has suitable flight characteristics.

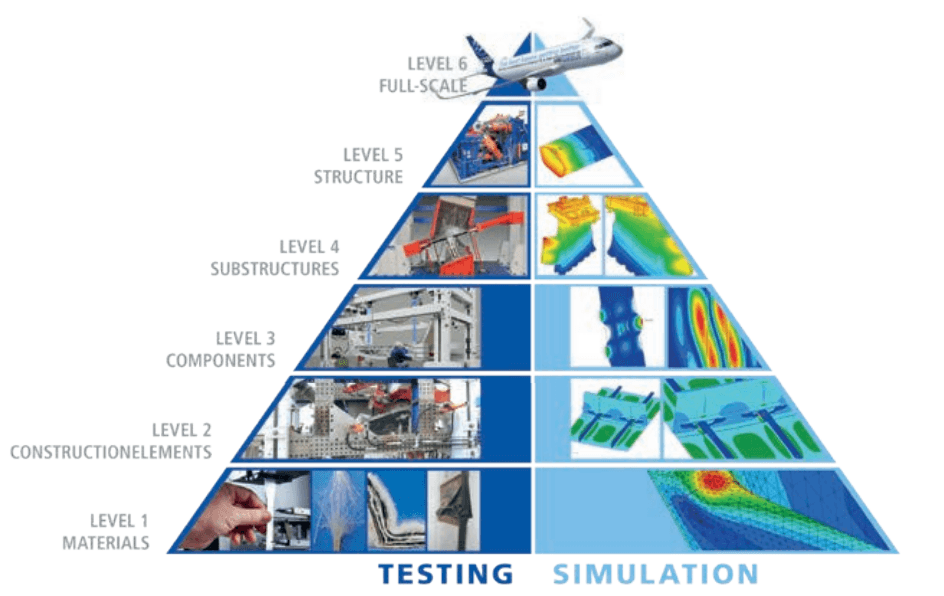

The structural integrity testing pyramid

From a structural point of view, manufacturers are required to document every step of the design process from materials coupon testing to full aircraft flights. In modern aircraft, a blend of simulation and physical testing is used to make this process as efficient as possible.

CFD plays a key role in the process by generating flight load cases for the different sign-off criteria. Take-off, landing, cruise, stall and even taxiing will present different loads to different parts of the airframe. Even with a physical aircraft it is difficult to measure these loads, so CFD is used extensively to help engineers decide how to test each part.

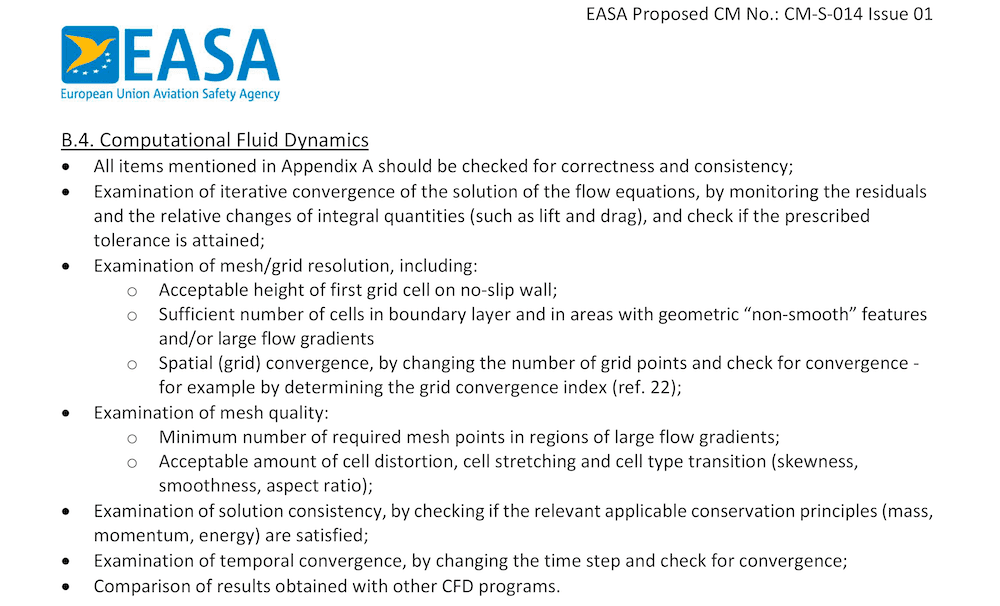

Certifying the use of CFD

Simulation tools are now used so frequently to support the certification process, regulatory bodies have had to specify the requirements of suitable CFD and FEA software packages. This ensures that only reliable and accurate codes are used by manufacturers to model scenarios and assess the flightworthiness of an aircraft.

In 2020, EASA issued a Notification of a Proposal to issue a Certification Memorandum on the subject of modelling and simulation. As well as demonstrating their aircraft is fit to fly, manufacturers also have to show that the analysis tools are accurate enough to calculate relevant load cases.

Could the future of certification be simulation only?

Simulation and physical testing is the accepted way of design and certifying a modern aircraft. For the future, the likelihood of simulation completely replacing physical testing is a constant topic of discussion.

"Simulations are becoming more complex and we are pushing the boundaries with physical testing, but will we ever certify an aircraft using simulation only?" questions Solar. "I'm not sure it will ever happen, actually. I think we must always check the results in the real world to validate the models, maybe less extensively than before in some areas, but for the extreme cases and conditions this needs to be checked by physical testing."

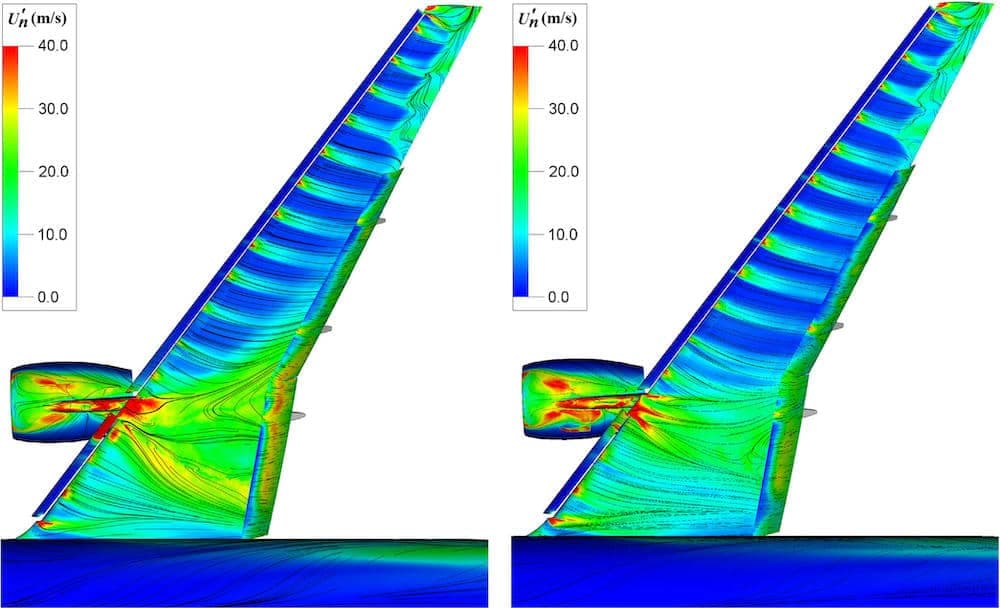

Physical testing also allows every detail of the design to be assessed because it requires real parts. Whereas CFD simulations often involve simplified models that may not capture all the intricacies of vortex generators and small gaps, which could affect the overall aerodynamics.

Extreme configurations at the limit of separation

Aircraft flight characteristics are of most interest to regulators at the extremes of performance, particularly in low-speed stall conditions and high speed transonic flow.

"There are still some configurations which are very difficult to simulate," highlights Solar. "Low speed is when you have the most complex wing configuration with perhaps single slotted, double slotted, triple slotted flaps, some slots with different extensions and multiple transitions usually with a high angle of attack. We can run simulations on a very small portion of the wing, but to simulate the full aircraft accurately requires a high amount of computing power which is the limit at the moment."

Computing power will continue to increase, making that last goal of a full aircraft simulation possible in the future. For now, CFD is a key contributor to aircraft safety, fitting alongside the other real world testing capabilities of modern aircraft manufacturers.

Interesting links:

- NASA Guide for Air Certification by Analysis

- NASA Computational Study of a Generic T-Tail Aircraft

- BAE Systems Heritage BAC1-11

- NASA flight research into icing

- Database of EASA Type Certificate Datasheets

References

[1] The Concorde Fleet - Breakdown of each air frame built. [Online]. Heritage Concorde.

[2] Test and Cetification. [Online]. Airbus.

[3] Proposed CM-S-014 Modelling & Simulation – for consultation. [Online]. EASA.

[4] Aircraft certification. [Online]. EASA.

[5] 2007. Certification Specifications for Large Aeroplanes CS-25. [Online]. EASA.

[6] 2016. Equivalent Safety Finding CS 25.251(b) - “Vibration / buffeting”. [Online]. EASA.