What is an aero map?

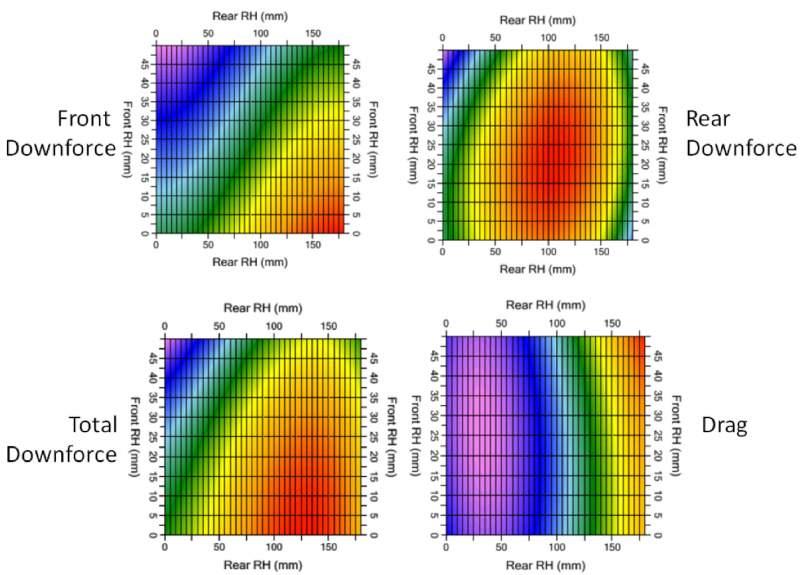

The most important parameters in race car aerodynamics are total downforce, aero balance and drag. At its simplest, these are related to the front and rear ride heights which can be visualised through 3D maps.

Ride heights have a big effect on the aerodynamic characteristics and are directly linked to car speed via the suspension set-up, which can be adjusted. In Formula 1 for example, where fine details mean everything, maps can be multi-dimensional; adding yaw, steer and roll dependencies.

An individual aero map represents a specific mechanical car configuration. Changing bodywork elements like cooling exits and rear wing types, or settings like splitter and front wing angles creates a new map. This new map can change in both magnitude and shape.

Why do we care?

All aero maps have a load peak, which is the pair of ride heights where the car generates maximum downforce. More downforce means more grip translated to the tyres and faster lap times. Knowing the location of this peak and how downforce varies across the ride height range is arguably the most important piece of information about a race car.

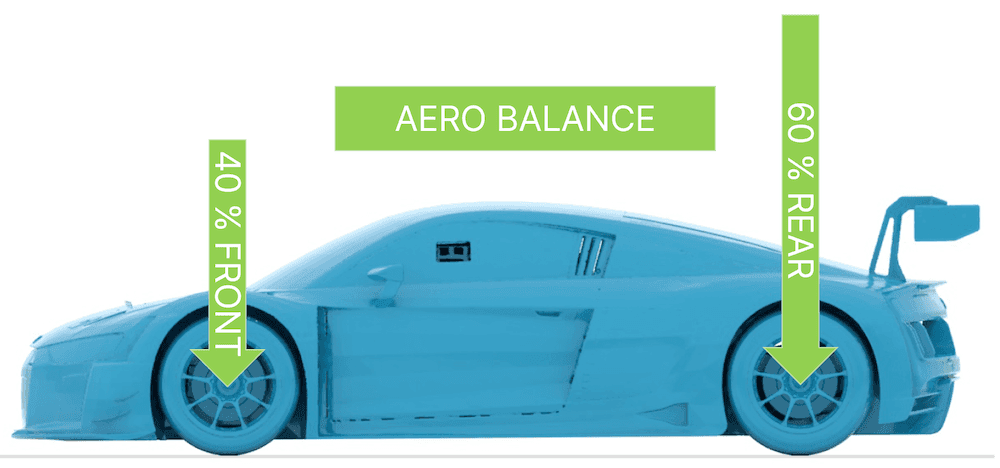

However, downforce alone doesn’t guarantee a fast car, you need to achieve the optimum aero balance. This defines how the aerodynamic load is split between the front and rear axles.

Most cars have an uneven split of downforce front to rear which doesn’t remain constant across the ride height range. This changes the car’s understeer/oversteer balance at different cornering speeds. Managed badly, the driver won’t be able to use all of the available downforce.

How do race engineers use aero maps?

Ideally, the car would be set up to always run at the peak of the map, but usually, this isn’t possible. Tyres have compliance and the suspension has springs for ride and handling purposes. As downforce increases with the square of speed, ride heights become lower as the car accelerates. Therefore, unless the car has active suspension, it can’t remain at the peak point of the aero map all of the time.

The race engineer’s job is to tune the set-up of ride heights and spring rates to ensure that the car achieves the optimum position on the aero map. As most lap time gains can be found in low-speed corners, the car will be set up to be near the optimum downforce-producing ride heights at these speeds.

How a car traverses the ride height space is also important from a car balance point of view. Ideally, car design and set-up will allow the car to run along lines of equal balance on the aero balance map. This means the car will feel the same through a braking event and in corners of different speeds. This gives the driver confidence to push to the maximum in every corner.

Most cars produce the least drag when the ride heights are level front to rear to give the smallest frontal area. Some cars will also have diffusers that stall at low rear ride heights, reducing drag further. On high-speed tracks such as Monza or Baku, engineers may run very soft rear springs to run as low as possible on the straights to stall the diffuser. This must be tuned using the drag map to avoid it happening in the corners.

How do we choose the right settings?

The simplest way to juggle all of the requirements is to use lap time simulation. This is where an engineer runs a car model around a circuit trajectory and sweeps through the aero maps for all set-ups of the car.

This gives a series of lap time results which helps the engineer choose the rear wing configuration that gives the best lap time, trading between straight line speed and corner speed. For Monza, this usually means a skinny rear wing due to the long straights, while Monaco’s slow corners mean the highest rear wing level possible.

How do you create a map?

The detailed maps used in F1 require complicated wind tunnel runs to generate hundreds of test points. The resulting expense of detailed models and tunnel time is way beyond most motorsport teams and even manufacturers. Often, comprehensive data is reserved for factory teams and not customers.

Computing power and software development mean it is now possible to improve upon the data available by using off-the-shelf CFD products. Airshaper makes it simple for users to import 3D car models and carry out multiple mapping runs. 3D CAD for many customer cars can be sourced from professional modellers and modified within the software to create different configurations.

With this power, it is simple for the user to make the changes required to sweep through all of the different configurations and ride height combinations. Processed results create maps of downforce, balance and drag. Armed with these, it is possible to fully explore the performance envelope of the car using simulation and logged data.